Certification & Test

Material Test

1. Material

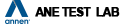

test ---- Needle flame test

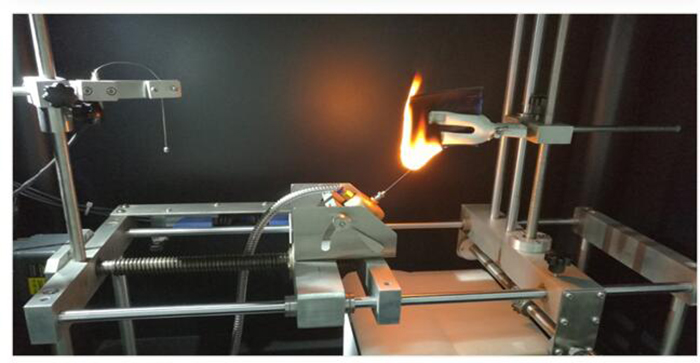

2. Material test ---- Glow wire test

According to standard IEC60695-10-2

"fire hazard test Part 10-2: thermal anomaly ball pressure test

method", the structural characteristics of the nonmetal and insulating

materials are subject to change under the effect of high temperature. This

change is usually manifested in forms of softening or melting. The ball

pressure test is used to test the heat-resistant properties of nonmetallic

materials and insulating materials. In the standards of GB2099.1.1996,

GB19212.1.2003, GB4943. 2001 and GB15092.1-2000, there is a clear requirement

for the heat resistance of the metallic material and the insulating material, and

pressure test is essential.

The sample is placed in a horizontal

position and the 5mm diameter steel ball is pressed on the surface of the

sample with 20N pressure. This test should be carried out in the heating box

and the temperature is 75 ℃ ± 2 ℃.

The diameter of the indentation was measured

1 hours after the action of the steel ball. The test fails when the

diameter of the indentation is larger than 2mm.

Based on standard IEC60695-11-5 fire

hazard test part 11-5: needle flame test method, device, verification test

agreement and guide,the needle flame test is

suitable for insulation materials, engineering plastics or other solid

combustible materials industry.

The needle flame test is based on the

IEC60695 -11-5; GB/T5169.5-2008, GB4706.1-2005 and other standards used in the

small flame ignition source simulation test project. Needle flame test is to

use apparatus with specified size (diameter 0.9mm) needle burner, with specific

gas (butane), with 45 degree angle orientation application sample as the sample

gas, to test the ignition and the burning time and burning length to evaluate

the small flame equipment caused by internal fault conditions of the fire

danger. Needle flame test applies to lighting, low-voltage electrical

appliances, household appliances, electrical tools, electric motor, electric

tools, electronic instruments, electrical instruments, electrical connector

such as electrical and electronic equipment and parts, components of the

research, production and quality inspection departments, and can also be

applied to insulation materials, engineering plastics or other solid

combustible materials industry.

According to the standard

IEC60695-2-11 , fire hazard test -- part 2-11 -- test method based on glow wire

/ heating wire -- glow wire flammability test of final product.

The device is designed according to

the requirements of the IEC60695-2-10:2000, GB/T5169.10-2006, GB/T5169.13-2006

and GB4706.1 in the standard "glow wire test method" , applicable to

electrical and electronic products, household appliances and materials for fire

hazard testing, heat source or sources of ignition burning or overload

resistance simulation components such as caused by thermal stress in a short

time.

The glow wire tester is to simulate

insulating material or other solid combustible material, which is easy to

spread flame inside the equipment, and may be ignited by hot wire or burning

element. Under certain conditions, such as fault current passing through the

conductor, overload of components and loose contact, some components will reach

a certain temperature and make the parts near the ignition test.

The working principle of glow wire

test instrument: 4 mm nichrome wire (U type glow wire head) heated to the

specified temperature (300 ℃ to 1000 ℃)

with high current heat , under required pressure (1.0N) level, burn the subject

30s, test it whether ignite or hold burning time of fire to judge the

flammability hazard of electrical and electronic equipment products; after

completion of the burning test, record the ignition time (Ti), the fire

extinguishing time (Te), and flammability index (GWFI).

Glow wire head: nominal diameter for

armored thermocouple wire for 0.5mm, nickel chromium and nickel aluminum (K)

wire, suitable for continuous operation at temperatures up to 960℃,

the welding point in their armored sleeve for thermocouple measurement glow

wire temperature, its armor the metal can stand at least 1050 ℃.

Calibrate

glow wire temperature:

1. put the standard silver foil (99.8%

purity and thickness of 0.06mm, the side of 2mm Square) on the top of the

center of glow wire head.

2. glow wire head is heated to a

suitable value until the silver foil melts, and value thermometer displayed

should be the standards of 960 ±15℃.

(Note: the metal of its armoured sleeve of

thermocouple should at least bear 1050 degrees of temperature. Imported

thermocouple is recommended.)

3. Material test ---- Ball pressure test